PVC Screen / Casing™

Boode Select PVC well screen and casing is manufactured from carefully selected materials. The combination of the highest grade compounds, calcium zinc-based stabilisers and the latest extrusion, slotting and threading technology makes Boode products the finest in the world.

Boode Select PVC well screen and casing is manufactured from carefully selected materials. The combination of the highest grade compounds, calcium zinc-based stabilisers and the latest extrusion, slotting and threading technology makes Boode products the finest in the world.

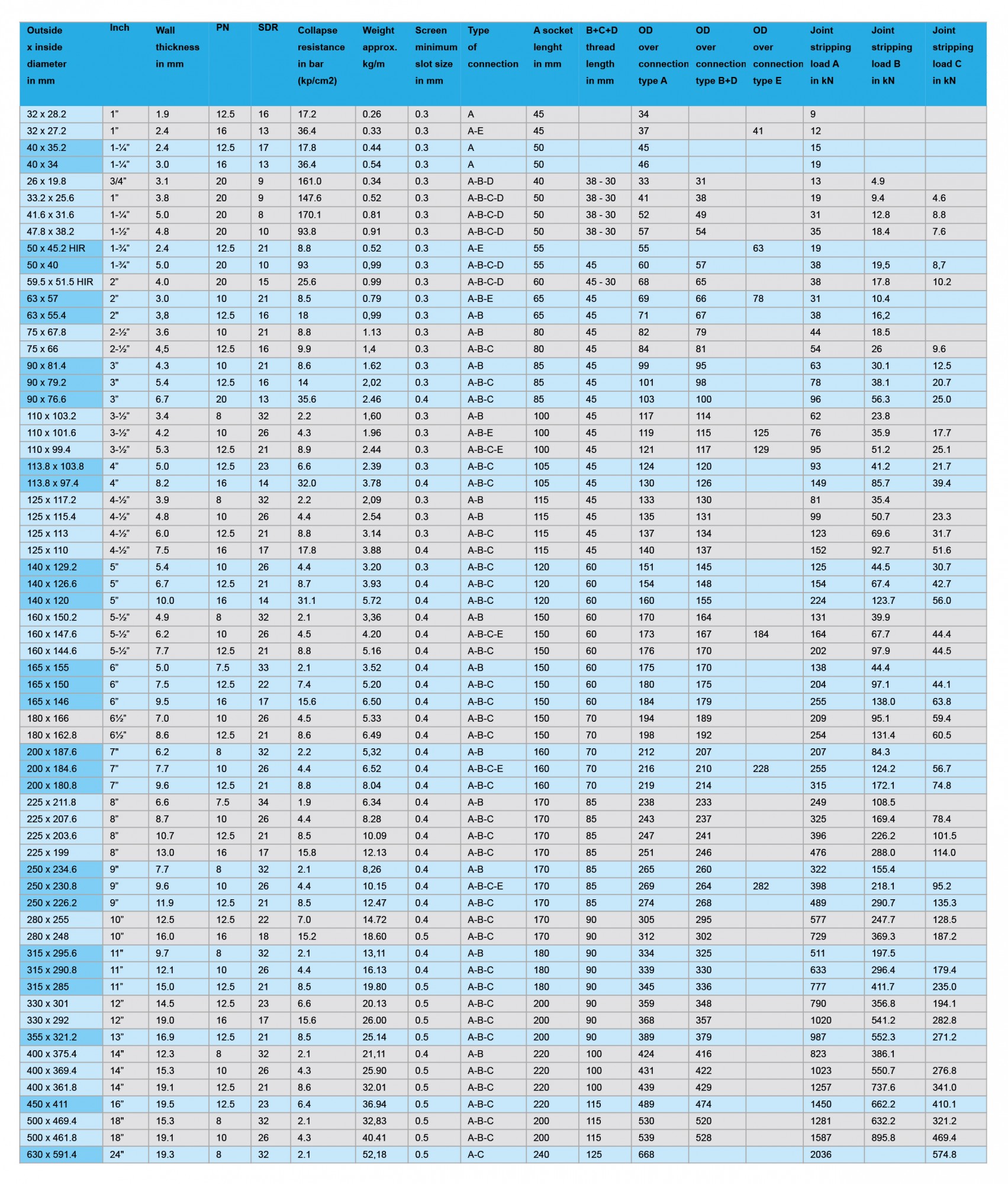

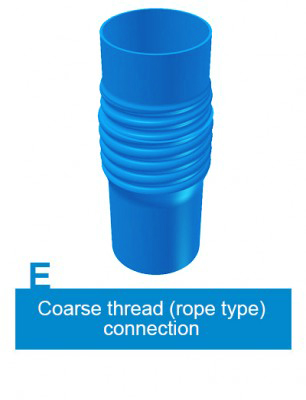

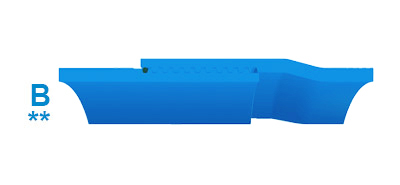

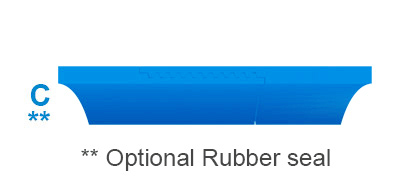

Boode Select PVC screen and casing is available in a range of threaded connections with the highest joint stripping loads or for solvent welding utilising a specially developed solvent. Boode’s solvent weld connection (Type A) is one of the strongest connections on the market.

Boode Select PVC screen and casing is available up to 630mm (24”) and can be installed to depths in excess of 300 metres.

Applications:

Water wells, dewatering, geothermal systems, water abstraction wells, recharge wells, monitoring boreholes, well point dewatering, deep well dewatering, salt water intakes, pressure relief wells, aquifer storage & recovery wells and for irrigation purposes.

Advantages of Boode Screen and Casing:

- Safe, legal & compliant for potable water abstraction

- Maximum tensile strength, collapse resistance and joint stripping loads.

- Highest quality lead free PVC compounds

- Smallest possible screen slots on the market

- Strongest threaded & solvent weld connections on the market

- Cost-effective and long lasting

- Makes installation fast, easy and low in cost

- Fully approved to Regulation 31, KIWA and BS6920

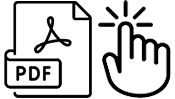

Technical details PVC Screen / Casing

| Inch | 1” | 1” | 1-¼” | 1-¼” | 3/4” | 1” | 1-¼” | 1-½” | 1-¾” | 1-¾” | 2” | 2” | 2" | 2-½” | 2-½” | 3” | 3" | 3” | 3-½” | 3-½” | 3-½” | 4” | 4” | 4-½” | 4-½” | 4-½” | 4-½” | 5” | 5” | 5” | 5-½” | 5-½” | 5-½” | 6” | 6” | 6” | 6½” | 6½” | 7" | 7” | 7” | 8” | 8” | 8” | 8” | 9" | 9” | 9” | 10” | 10” | 11" | 11” | 11” | 12” | 12” | 13” | 14" | 14” | 14” | 16” | 18" | 18” | 24" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outside x inside diameter in mm | 32 x 28.2 | 32 x 27.2 | 40 x 35.2 | 40 x 34 | 26 x 19.8 | 33.2 x 25.6 | 41.6 x 31.6 | 47.8 x 38.2 | 50 x 45.2 HIR | 50 x 40 | 59.5 x 51.5 HIR | 63 x 57 | 63 x 55.4 | 75 x 67.8 | 75 x 66 | 90 x 81.4 | 90 x 79.2 | 90 x 76.6 | 110 x 103.2 | 110 x 101.6 | 110 x 99.4 | 113.8 x 103.8 | 113.8 x 97.4 | 125 x 117.2 | 125 x 115.4 | 125 x 113 | 125 x 110 | 140 x 129.2 | 140 x 126.6 | 140 x 120 | 160 x 150.2 | 160 x 147.6 | 160 x 144.6 | 165 x 155 | 165 x 150 | 165 x 146 | 180 x 166 | 180 x 162.8 | 200 x 187.6 | 200 x 184.6 | 200 x 180.8 | 225 x 211.8 | 225 x 207.6 | 225 x 203.6 | 225 x 199 | 250 x 234.6 | 250 x 230.8 | 250 x 226.2 | 280 x 255 | 280 x 248 | 315 x 295.6 | 315 x 290.8 | 315 x 285 | 330 x 301 | 330 x 292 | 355 x 321.2 | 400 x 375.4 | 400 x 369.4 | 400 x 361.8 | 450 x 411 | 500 x 469.4 | 500 x 461.8 | 630 x 591.4 |

| Wall thickness in mm | 1.9 | 2.4 | 2.4 | 3.0 | 3.1 | 3.8 | 5.0 | 4.8 | 2.4 | 5.0 | 4.0 | 3.0 | 3,8 | 3.6 | 4,5 | 4.3 | 5.4 | 6.7 | 3.4 | 4.2 | 5.3 | 5.0 | 8.2 | 3.9 | 4.8 | 6.0 | 7.5 | 5.4 | 6.7 | 10.0 | 4.9 | 6.2 | 7.7 | 5.0 | 7.5 | 9.5 | 7.0 | 8.6 | 6.2 | 7.7 | 9.6 | 6.6 | 8.7 | 10.7 | 13.0 | 7.7 | 9.6 | 11.9 | 12.5 | 16.0 | 9.7 | 12.1 | 15.0 | 14.5 | 19.0 | 16.9 | 12.3 | 15.3 | 19.1 | 19.5 | 15.3 | 19.1 | 19.3 |

| PN | 12.5 | 16 | 12.5 | 16 | 20 | 20 | 20 | 20 | 12.5 | 20 | 20 | 10 | 12.5 | 10 | 12.5 | 10 | 12.5 | 20 | 8 | 10 | 12.5 | 12.5 | 16 | 8 | 10 | 12.5 | 16 | 10 | 12.5 | 16 | 8 | 10 | 12.5 | 7.5 | 12.5 | 16 | 10 | 12.5 | 8 | 10 | 12.5 | 7.5 | 10 | 12.5 | 16 | 8 | 10 | 12.5 | 12.5 | 16 | 8 | 10 | 12.5 | 12.5 | 16 | 12.5 | 8 | 10 | 12.5 | 12.5 | 8 | 10 | 8 |

| SDR | 16 | 13 | 17 | 13 | 9 | 9 | 8 | 10 | 21 | 10 | 15 | 21 | 16 | 21 | 16 | 21 | 16 | 13 | 32 | 26 | 21 | 23 | 14 | 32 | 26 | 21 | 17 | 26 | 21 | 14 | 32 | 26 | 21 | 33 | 22 | 17 | 26 | 21 | 32 | 26 | 21 | 34 | 26 | 21 | 17 | 32 | 26 | 21 | 22 | 18 | 32 | 26 | 21 | 23 | 17 | 21 | 32 | 26 | 21 | 23 | 32 | 26 | 32 |

| Collapse resistance in bar (kp/cm2) | 17.2 | 36.4 | 17.8 | 36.4 | 161.0 | 147.6 | 170.1 | 93.8 | 8.8 | 93 | 25.6 | 8.5 | 18 | 8.8 | 9.9 | 8.6 | 14 | 35.6 | 2.2 | 4.3 | 8.9 | 6.6 | 32.0 | 2.2 | 4.4 | 8.8 | 17.8 | 4.4 | 8.7 | 31.1 | 2.1 | 4.5 | 8.8 | 2.1 | 7.4 | 15.6 | 4.5 | 8.6 | 2.2 | 4.4 | 8.8 | 1.9 | 4.4 | 8.5 | 15.8 | 2.1 | 4.4 | 8.5 | 7.0 | 15.2 | 2.1 | 4.4 | 8.5 | 6.6 | 15.6 | 8.5 | 2.1 | 4.3 | 8.6 | 6.4 | 2.1 | 4.3 | 2.1 |

| Weight approx. kg/m | 0.26 | 0.33 | 0.44 | 0.54 | 0.34 | 0.52 | 0.81 | 0.91 | 0.52 | 0,99 | 0.99 | 0.79 | 0,99 | 1.13 | 1,4 | 1.62 | 2,02 | 2.46 | 1,60 | 1.96 | 2.44 | 2.39 | 3.78 | 2,09 | 2.54 | 3.14 | 3.88 | 3.20 | 3.93 | 5.72 | 3,36 | 4.20 | 5.16 | 3.52 | 5.20 | 6.50 | 5.33 | 6.49 | 5,32 | 6.52 | 8.04 | 6.34 | 8.28 | 10.09 | 12.13 | 8,26 | 10.15 | 12.47 | 14.72 | 18.60 | 13,11 | 16.13 | 19.80 | 20.13 | 26.00 | 25.14 | 21,11 | 25.90 | 32.01 | 36.94 | 32,83 | 40.41 | 52,18 |

| Screen minimum slot size in mm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.3 | 0.3 | 0.4 | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Type of connection | A | A-E | A | A | A-B-D | A-B-C-D | A-B-C-D | A-B-C-D | A-E | A-B-C-D | A-B-C-D | A-B-E | A-B | A-B | A-B-C | A-B | A-B-C | A-B-C | A-B | A-B-E | A-B-C-E | A-B-C | A-B-C | A-B | A-B | A-B-C | A-B-C | A-B-C | A-B-C | A-B-C | A-B | A-B-C-E | A-B-C | A-B | A-B-C | A-B-C | A-B-C | A-B-C | A-B | A-B-C-E | A-B-C | A-B | A-B-C | A-B-C | A-B-C | A-B | A-B-C-E | A-B-C | A-B-C | A-B-C | A-B | A-B-C | A-B-C | A-B-C | A-B-C | A-B-C | A-B | A-B-C | A-B-C | A-B-C | A-B-C | A-B-C | A-C |

| A socket lenght in mm | 45 | 45 | 50 | 50 | 40 | 50 | 50 | 50 | 55 | 55 | 60 | 65 | 65 | 80 | 80 | 85 | 85 | 85 | 100 | 100 | 100 | 105 | 105 | 115 | 115 | 115 | 115 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 160 | 160 | 160 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 170 | 180 | 180 | 180 | 200 | 200 | 200 | 220 | 220 | 220 | 220 | 200 | 200 | 240 |

| B+C+D thread length in mm | 38 - 30 | 38 - 30 | 38 - 30 | 38 - 30 | 45 | 45 - 30 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 100 | 100 | 100 | 115 | 115 | 115 | 125 | |||||

| OD over connection type A | 34 | 37 | 45 | 46 | 33 | 41 | 52 | 57 | 55 | 60 | 68 | 69 | 71 | 82 | 84 | 99 | 101 | 103 | 117 | 119 | 121 | 124 | 130 | 133 | 135 | 137 | 140 | 151 | 154 | 160 | 170 | 173 | 176 | 175 | 180 | 184 | 194 | 198 | 212 | 216 | 219 | 238 | 243 | 247 | 251 | 265 | 269 | 274 | 305 | 312 | 334 | 339 | 345 | 359 | 368 | 389 | 424 | 431 | 439 | 489 | 530 | 539 | 668 |

| OD over connection type B+D | 31 | 38 | 49 | 54 | 57 | 65 | 66 | 67 | 79 | 81 | 95 | 98 | 100 | 114 | 115 | 117 | 120 | 126 | 130 | 131 | 134 | 137 | 145 | 148 | 155 | 164 | 167 | 170 | 170 | 175 | 179 | 189 | 192 | 207 | 210 | 214 | 233 | 237 | 241 | 246 | 260 | 264 | 268 | 295 | 302 | 325 | 330 | 336 | 348 | 357 | 379 | 416 | 422 | 429 | 474 | 520 | 528 | ||||||

| OD over connection type E | 41 | 63 | 78 | 125 | 129 | 184 | 228 | 282 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Joint stripping load A in kN | 9 | 12 | 15 | 19 | 13 | 19 | 31 | 35 | 19 | 38 | 38 | 31 | 38 | 44 | 54 | 63 | 78 | 96 | 62 | 76 | 95 | 93 | 149 | 81 | 99 | 123 | 152 | 125 | 154 | 224 | 131 | 164 | 202 | 138 | 204 | 255 | 209 | 254 | 207 | 255 | 315 | 249 | 325 | 396 | 476 | 322 | 398 | 489 | 577 | 729 | 511 | 633 | 777 | 790 | 1020 | 987 | 823 | 1023 | 1257 | 1450 | 1281 | 1587 | 2036 |

| Joint stripping load B in kN | 4.9 | 9.4 | 12.8 | 18.4 | 19,5 | 17.8 | 10.4 | 16,2 | 18.5 | 26 | 30.1 | 38.1 | 56.3 | 23.8 | 35.9 | 51.2 | 41.2 | 85.7 | 35.4 | 50.7 | 69.6 | 92.7 | 44.5 | 67.4 | 123.7 | 39.9 | 67.7 | 97.9 | 44.4 | 97.1 | 138.0 | 95.1 | 131.4 | 84.3 | 124.2 | 172.1 | 108.5 | 169.4 | 226.2 | 288.0 | 155.4 | 218.1 | 290.7 | 247.7 | 369.3 | 197.5 | 296.4 | 411.7 | 356.8 | 541.2 | 552.3 | 386.1 | 550.7 | 737.6 | 662.2 | 632.2 | 895.8 | ||||||

| Joint stripping load C in kN | 4.6 | 8.8 | 7.6 | 8,7 | 10.2 | 9.6 | 12.5 | 20.7 | 25.0 | 17.7 | 25.1 | 21.7 | 39.4 | 23.3 | 31.7 | 51.6 | 30.7 | 42.7 | 56.0 | 44.4 | 44.5 | 44.1 | 63.8 | 59.4 | 60.5 | 56.7 | 74.8 | 78.4 | 101.5 | 114.0 | 95.2 | 135.3 | 128.5 | 187.2 | 179.4 | 235.0 | 194.1 | 282.8 | 271.2 | 276.8 | 341.0 | 410.1 | 321.2 | 469.4 | 574.8 |

Scroll the table from right to left.

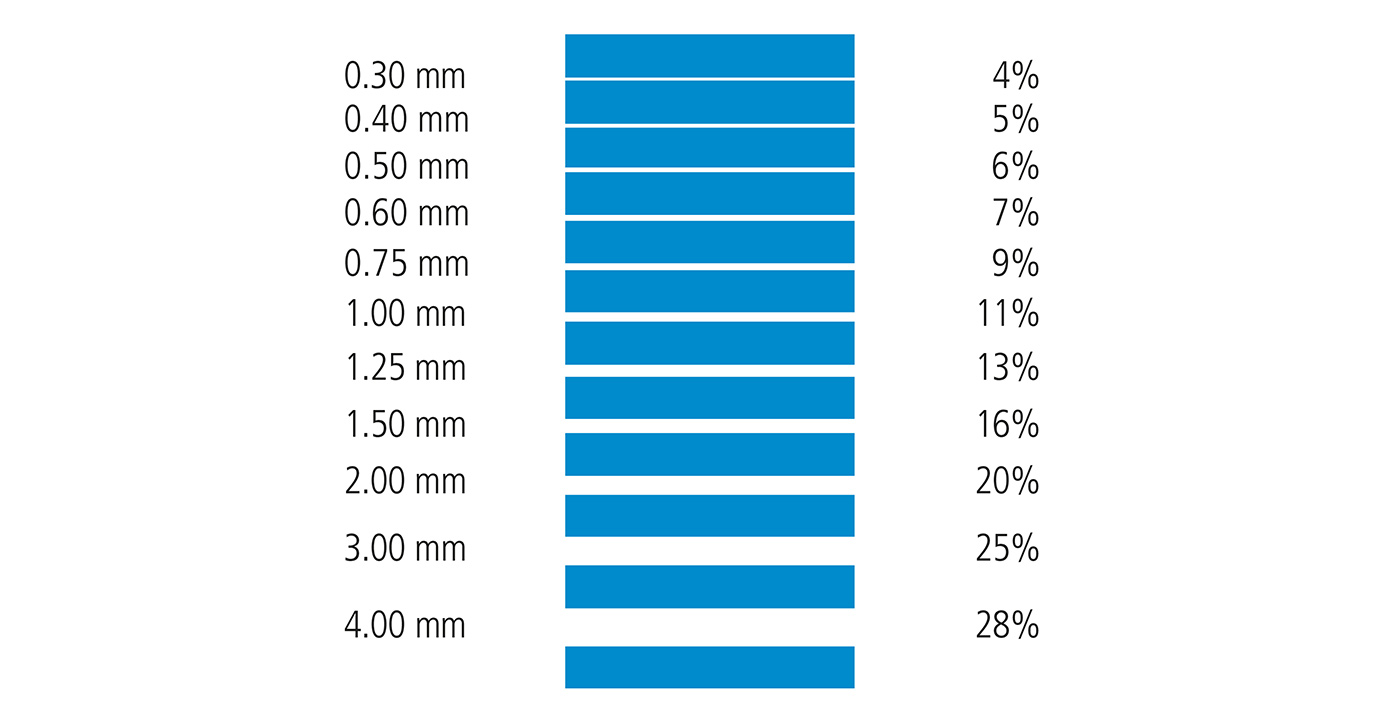

Standard slot width range showing average percentage open area.